Introduction: The Common Dilemmas in Automation

Imagine a factory line where machines falter under pressure—parts misaligned, delays piling up. Statistically, inefficiencies in automation result in losses exceeding 20% of operational time. An electric gripper promises enhanced precision and reliability, yet many remain unaware of its full potential. Why do failures always occur during critical phases of production? Look, it’s simpler than you think; enlightenment starts with understanding the technology. By integrating advanced solutions, we can indeed elevate the capabilities of our automation systems.

Body: Understanding Electric Grippers and Their Advantages

Traditional Solutions and Their Flaws

For decades, industries relied on pneumatic and hydraulic grippers, which often present significant challenges—namely, their lack of responsiveness and increased maintenance needs. These systems can be bulky and prone to leakage, creating not just operational issues but also safety hazards.

New Technology Principles Behind Electric Grippers

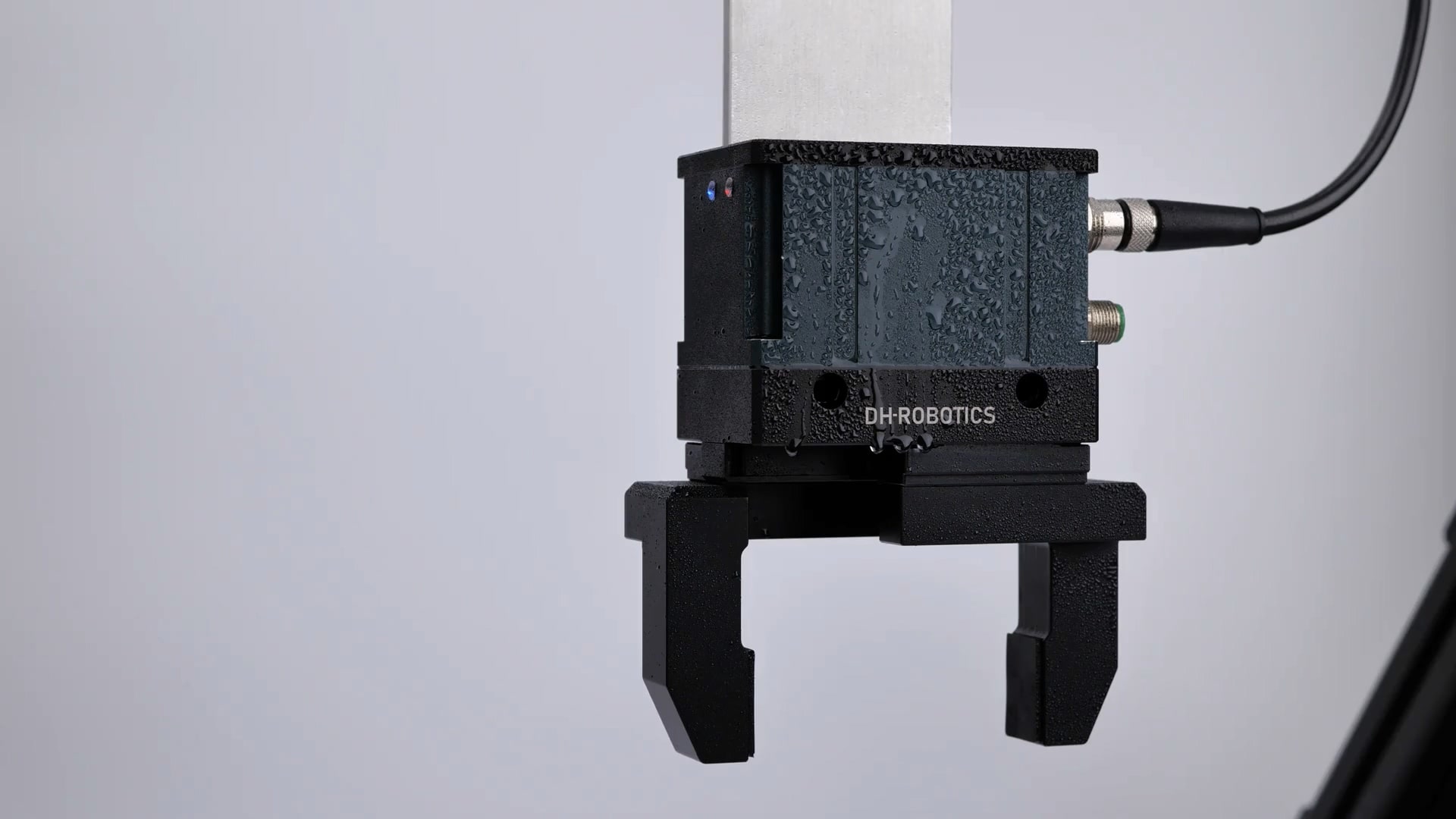

Electric grippers leverage a clean, compact design that employs precise motors and sensors, ensuring that operations are efficient and adaptable. With features such as programmability, they can be tailored to various industrial tasks, a stark contrast to traditional systems. This adaptability is crucial in modern manufacturing, where speed and precision are paramount.

Quantified User Benefits

Users of electric grippers have reported reduced downtime by up to 30%—and with minimal maintenance requirements, the cost-effectiveness becomes evident. These devices not only improve speed but also enhance accuracy, leading to fewer product defects. Such improvements are critical in sectors like automotive and electronics, where precision rules.

Conclusion: Evaluating Your Automation Needs

Before integrating a gripping solution, always verify these three metrics when choosing solutions: ① compatibility with existing systems, ② scalability potential, and ③ expected return on investment. By focusing on these criteria, businesses can make informed decisions that enhance their operational capabilities.

Electric Actuator Gripper: The Versatile Choice

The design and functionality of an electric actuator gripper make it a vital element in various applications—from assembly to packaging. Think about biocompatibility in medical settings—a robust electric actuator gripper can adapt to cleanroom requirements, upholding stringent hygiene standards. Furthermore, the ease of integration with current automation frameworks means businesses can retrofit existing systems without extensive overhauls. Isn’t it refreshing to have a tool that not only enhances efficiency but also ensures reliability? This level of adaptability is essential in today’s fast-paced industrial landscape.

Electric Robot Grippers: Embracing Innovation

As industries evolve, the role of electric robot grippers in automation becomes ever more critical. These devices allow for intricate manipulation of components, proving instrumental in tasks that require high precision. By utilizing sophisticated sensor technology, electric robot grippers can identify and react to their environment, which significantly reduces the risk of errors during automated processes. Moreover, they often come equipped with advanced features such as real-time feedback, enabling operators to make immediate adjustments as needed. This capability is particularly beneficial in operations where rapid response times are essential, ensuring high productivity and minimal wastage.

Summary and Future Considerations

In summary, electric grippers represent the future of automation—offering improved performance, efficiency, and versatility suitable for diverse industries. With the continued advancements in technology, opting for a manufacturer like DH-Robotics ensures that you exploit the advantages of these mechanical wonders to their fullest potential. Their products not only provide a leading edge in terms of innovation but also unparalleled supply advantages, positioning your operations for success in an increasingly competitive landscape.